OUR VERY BEST. CONSTANTLY FOR YOU.

SQUARE METERS | CUBIC METERS | TONS

Storage capacity

On our premises in Hamm we have plenty of space:

On our premises in Hamm we have plenty of space:

approximately 50,000 m2 of storage space with a capacity of more than 200,000t, of which 150,000 t in covered warehouses will house your materials. Thus, the raw materials – especially the magnesite – are protected from moisture.

In addition, around 2,000 t of storage capacity is available in silos for finished goods.

- Radlager beim Transport im Aussenlager

- Einlagerung des Sintermagnesits

- 4 Radlader sind bei MMW für Einlagerungen und Materialtransporte im Einsatz

- Beladung eines LKWs mit Rohware

- Vorratssilos für Fertigware

BREAKING | DRYING | MAHLEN | to sieve

ON A PRODUCTION LINE

In our three pre-breakers, blocks with an edge length of up to one meter can be broken.

In our three pre-breakers, blocks with an edge length of up to one meter can be broken.

The varietal processing is then carried out on seven combined drying, grinding and screening plants: four processing lines are available for MgO products, and three further plantsfor Al2O3 products.

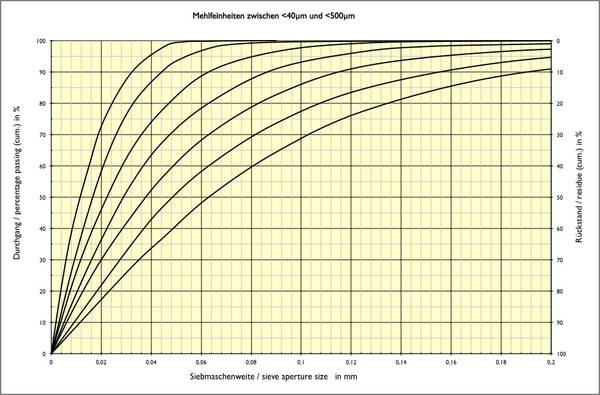

For the grinding of the minerals, we use six ball mills on which flour fineness between 40 microns and 500 microns can be achieved, depending on the customer’s wash. Our highly flexible screening machines can produce grains from 0-0.2 to 8-15 mm.

In principle, production is also possible according to your specific specifications.

In total, we achieve a processing capacity of more than 200,000 t per year on all plants.

- Auf den Kugelmühlen können stündlich zwischen 1t und 5t Mineralmehl produziert werden

- Moderne Anlagensteuerungstechnik

- Das „Innenleben“ einer Magnesit-Mahlanlage

- Produktionssiebe mit verschiedenen Maschenweiten

- Hochflexible Siebmaschinen für variable Körnungen

- Verschiedene Mehlfeinheiten können nach Kundenwunsch abgestimmt werden

- Wir produzieren bis zu 1.000 Tonnen Fertiggut – pro Tag.

LOOSE SILOWARE | PAPER SACK | BIG BAG

READY FOR TRANSPORT AS DESIRED

READY FOR TRANSPORT AS DESIRED

Our products allow us a high degree of flexibilitywhen it comes to packaging and transport. Our regrind can be loosely filled directly into silo trucks or packed in paper bags or big bags for transport.

Are you looking for an individual packaging and transport solution?

We find a way together.

- Beladung eines Silo-LKW

- Befüllung von Papiersäcken in der Aufbereitungsanlage

- Papiersackverpackung

- Verpackung in Big-BagsVerpackung in Big-Bags

- Individuelle Verpackung nach Kundenwunsch

BECAUSE SAFE IS

CHARGE SECURITY CONFORM & DOCUMENTED

CHARGE SECURITY CONFORM & DOCUMENTED

Every load that leaves our premises is compliant and cleanly documented secured for transport.

In doing so, we comply with our operating instructions for the reliable loading of finished products.

CONTROLS – STEINHART & CERTIFIED

Certified quality management

Certified quality management

They place high demands on our regrind – and rightly so.

In order to meet these requirements, we have established a certified quality management system according to DIN EN ISO 9001:2008.

We will give you this in writing:

Download the certificate as PDF

EFFICIENT USE OF RESOURCES

Certified energy management

A modern company includes the careful use of energy resources in production.

For the preparation of refractory materials, we have introduced a certified energy management according to DIN EN ISO 50001.

Download the certificate as PDF:

TRUST IS GOOD, CONTROL IS BETTER

Permanent checks

Permanent checks

All materials, both raw materials and processed products, are precisely controlled in the company’s own modern chemical testing laboratory. This ensures that customer specifications and standards are met. The laboratory produces chemical analyses using x-ray fluorescence analysis (RFA)technology. In addition, other important material properties in the industry such as raw density, bulk weight, acid consumption, pH value, etc. can also be determined.

All raw materials are subjected to an incoming analysis during storage in the mineral mill. The sieve laboratory is available 24 hours a day for production control. There, grain distributions and grinding fines slabs are determined. It’s safe. The test laboratory ensures the consistently high quality of the products. On request, customers can also confirm this with a letter and seal.